In a groundbreaking development for the textile industry, C.L.A.S.S., an advocate for sustainable innovation, proudly highlights the achievements of its partner, ERCA Textile Chemical Solutions, with their latest innovation, REVE…

Menu

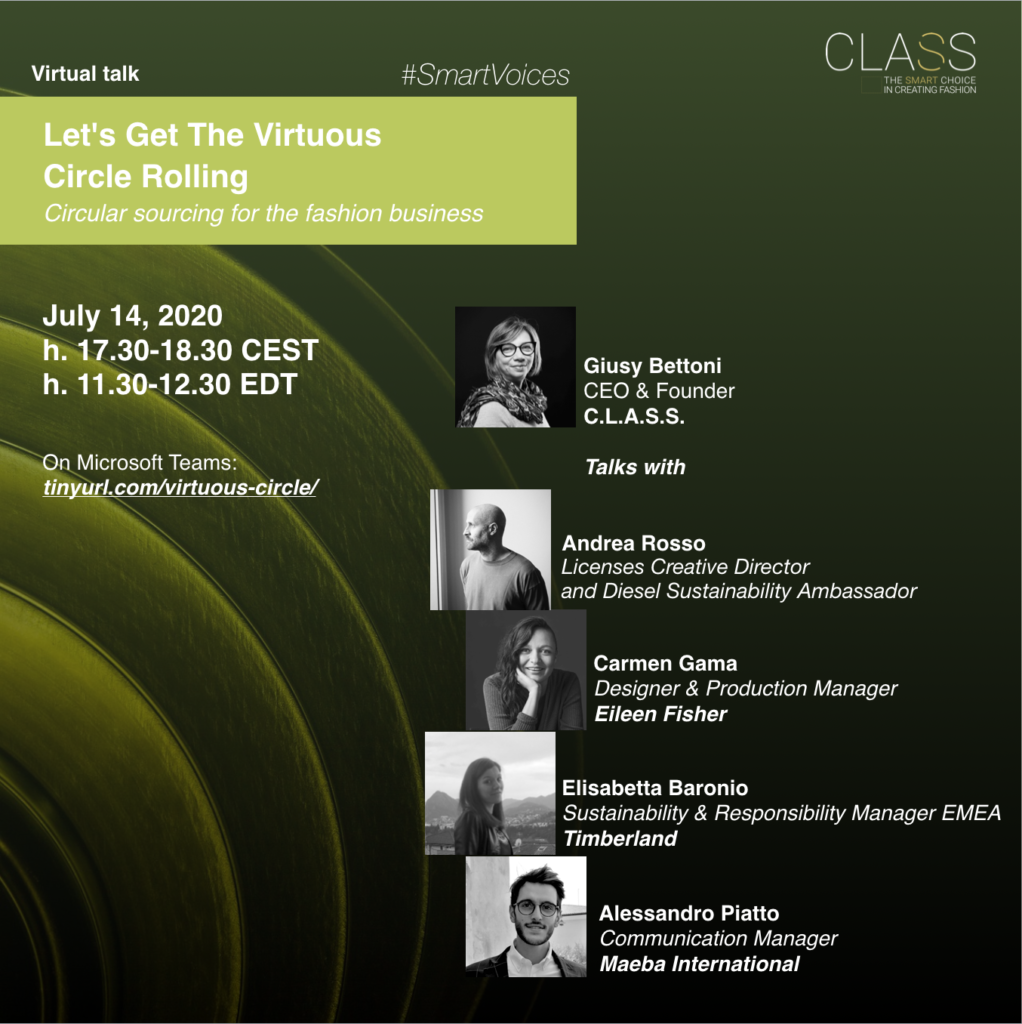

“Upcycling does not simply mean repurposing fabrics and reusing clothes, it’s the alternative way of making fashion smarter and circular” say influential speakers at C.L.A.S.S.’ virtual talk LET’S GET THE VIRTUOUS CIRCLE ROLLING

C.L.A.S.S. ecohub, Diesel, Eileen Fisher, Maeba International and Timberland presented their ultimate initiatives and offered their perspectives on Circular Economy. The event was part of the #SmartVoices program of digital talks with influential professionals who share their visions and goals to make the textile and fashion business more responsible

The session focused on a new way to look at alternative resources to production of brand-new fabrics and garment in a truly innovative way. “Nowadays, when you get to talk about recycled and upcycled fabrics or clothes, most people still think of poor or lower quality products”, provokes Giusy Bettoni. “This is far from reality and we must leave such ideas behind. Upcycling does not simply mean re-using clothes or repurposing fabrics, it’s the alternative way of making fashion smarter”. That’s why C.L.A.S.S.’ invited 4 innovators who truly integrated circular values in their business models and production strategy and developed ways to find resources at every level of their company and the production process”.

Timberland’s Elisabetta Baronio echoes: “Circular Economy is not only in the materials. It’s a philosophy and a model involving all the different departments of a company. That’s why at Timberland we involved all employees, from designers to marketing, R&D and financial units. All employees joined a Circular Economy educational program”. The brand has also teamed up with Christopher Raeburn, known for reworking surplus fabrics and garments. The British fashion designer has created a limited edition collection representing the brand’s commitment to making responsibly sourced products using recycled materials.

“Circular Economy is a way of thinking, designing and working, that we developed into a scalable waste-based design”, adds Carmen Gama at Eileen Fisher. “Actually, let’s stop calling it waste. The upcycled materials are a resource”. Eileen Fisher is a pioneer in Circular Economy: the American brand is known for having developed an innovative business model and pledges to implement circular design principles to create a closed-loop product offering.

The brand preserves the value of the clothes at every stage. “The RENEW collection comprises clothes designed to last. And when you’re done with them we take them back, in any condition, to be resold or renewed through techniques like overdyeing and mending. And the pieces we can’t use? We save every scrap, because they’re tomorrow’s raw materials. THE RESEWN collection is made from damaged garments resewn into new designs, just one of the solutions we’ve created to address the mounting problem of textile waste”.

“Upcycling is a new way for designers to create” said Andrea Rosso who doubles as a designer for his circular brand MyAr and sustainability ambassador at Diesel. The Myar brand has recently launched an all circular based collection. His brand Myar – the anagram of ‘army’ – is made from original recovered military apparel. By harnessing modern technology and sartorial workmanship, the collection offers a modern view of the past, refashioned tuning with circular economy values.

“It is said that everything starts from cleaning your room. In my case it was our warehouse. While making room I realized how much materials is accumulated and goes wasted and I realized that I had to do something about it” added Andrea.

With the DIESEL UPCYCLING FOR fashion project, the brand will release upcoming capsule collections each by a different designer, focused on reuse and sustainability. DIESEL UPCYCLING FOR 55DSL is the first in the series, partnering with 55DSL, the brand’s sporty sublabel from the ‘90s.

The fashion system is quite imperfect. Every day, tons of fabrics are produced to remain un-used and often discarded. “What we do at Maeba International is to collect and select materials from brands, producers and manufacturer, all rigorously premium quality and Made in Italy, to then create a smart archive of over 50.000 fabrics that is available for designers, brands and professionals striving to boost Circular Economy” said Alessandro Piatto of Maeba International, the stock specialist with over 50 years of experience.

Selected transparent and high-end materials have become a collection, ReLiveTex™, now also the first to be certified with the influential ISO14021, which grants total traceability.

“We have decided to feature the ReLiveTex™ collection in C.L.A.S.S’ Back In The Loop brand new platform featuring companies and innovators providing alternative circular resources” adds Giusy Bettoni. “BACK IN THE LOOP is the circular solution tweaking and optimizing the system’s process while creating an added value where it did not exist. A responsible act and an invite to integrate ethics to style. Our special partners at today for Back In The Loop are Maeba International and Mending For Good.”

There are also new innovative ways to bring forward Circular Economy shoes. With the Regenerative Agriculture project, Timberland takes responsibility on the land in order to give back to the environment. The brand announced a new partnership with the Savory Institute, a non-profit focused on the large-scale regeneration of the world’s grasslands. Regenerative grazing consists in managing the cattles in a way that mimics the natural movement of herd animals. This grazing allows for more rest and re-growth of grasses, leading to better food for livestock and healthier soil, as these grasses pull carbon out of the atmosphere and store it in the ground. These practices also support biodiversity and make the land more productive with greater resilience to both drought and heavy rain.

LET’S GET THE VIRTUOUS CIRCLE ROLLING virtual talk looked deep into the making of circular fashion highlighting how alternative resources have never been so important. “Customers are growing savvy (on sustainable alternative solutions)” said Carmen Gama. “They want to know! The world is yelling at us because we can’t overproduce anymore”.

It is time to go back in the loop!

Spiber Inc. with its “Brewed Protein™” materials is a game changer in the fashion industry

C.L.A.S.S. Material hub is our section dedicated to producers of innovative ingredients: fiber, yarn, fabri…

A project by Venezia da Vivere and a capsule collection made in Bemberg™ fabrics, designed by Tiziano Guardini with the illustrator Jacopo Ascari.

May 2023 – Bemberg™ by Asahi Kasei, the unique fiber ob…

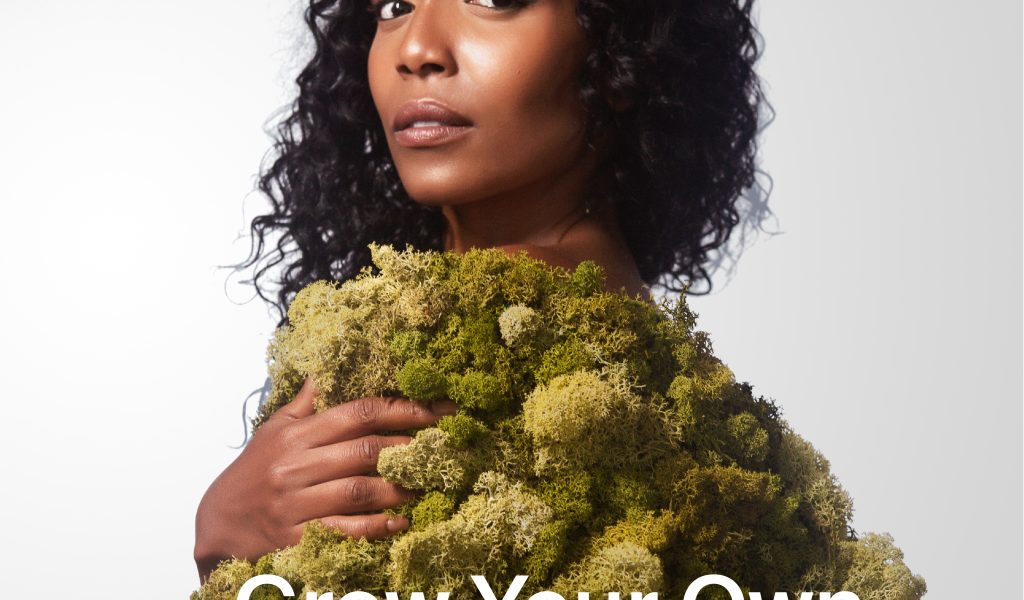

The award, now in its third edition, was set up by Connecting Cultures and C.L.A.S.S. with the aim of creating new visual imagery and innovative communication models in sustainable fashion

“Grow Your Couture” by Piero D’angelo, th…

Our CEO and Founder Giusy Bettoni has been really pleased to attend the 2nd Stakeholder Advisory Board Meeting of the MY-FI project held in Barcelona on May 4th at Leitat Technological Center!

We had the chance to meet the project members a…

Today we are happy to introduce you our new partner in our PROcess x PROgress category: REVECOL® by ERCA

As demonstration of ERCA TCS’s commitment towards responsible innovation, but also thanks to the important appreciation of its R&…

C.L.A.S.S. has always been committed to fostering and activating positive change in the fashion industry, while keeping contemporary consumers informed. This approach is perfectly aligned with the one of Challenge the Fabric that…

C.L.A.S.S. Material hub is our section dedicated to producers of innovative ingredients: fiber, yarn, fabric, leather and accessories.

Today we are happy to introduce you our new partner:

Pozzi Electa S.p.A.Pozzi Electa…

C.L.A.S.S. Material hub is our section dedicated to producers of innovative ingredients: fiber, yarn, fabric, leather and accessories.

Today we are happy to introduce you our new partner: Marini Industrie.

Marini Indust…

ROICA™ V550: the first Degradable Stretch solution for a New Generation of Denim

April 2023 – The international eco-tech yarn innovator and manufacturer ROICA™ by Asahi Kasei leads the way in circular stretch inno…

Since 2007 we have been advocating for a new generation of fashion where the fusion of design, innovation, communication and responsibility shapes an informed and competitive business, able to play both at an economic and social level.…

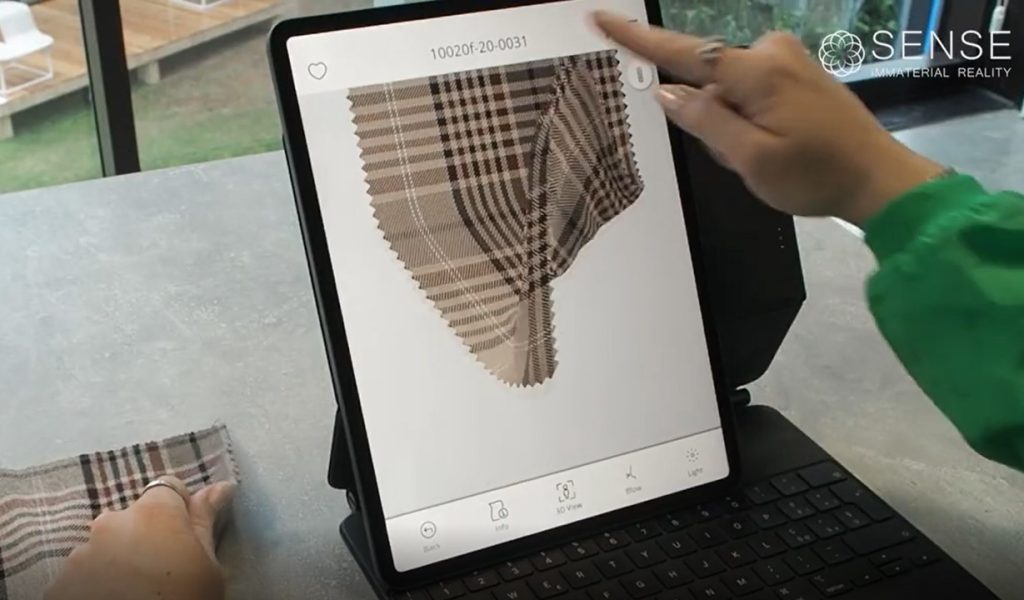

C.L.A.S.S. Future Devices is our area reserved for the new frontiers of digital communication: from virtual reality and haptics to blockchain platforms.

Today we are happy to introduce you our new partner:

Sense – im…