In a groundbreaking development for the textile industry, C.L.A.S.S., an advocate for sustainable innovation, proudly highlights the achievements of its partner, ERCA Textile Chemical Solutions, with their latest innovation, REVE…

Menu

Re.Verso by A. Stelloni Collection by Mapel

How a smart-oriented quality is achieving excellence

The result of advanced technology and the passion for noble raw materials and relentless research have always characterized the renowned textile company within the production of high quality fashion fabrics. Due to its continuous evolution, A. Stelloni Collection by Mapel arrives at Première Vision with an important change in terms of its collections’ offers.

The result of advanced technology and the passion for noble raw materials and relentless research have always characterized the renowned textile company within the production of high quality fashion fabrics. Due to its continuous evolution, A. Stelloni Collection by Mapel arrives at Première Vision with an important change in terms of its collections’ offers.

From recycled materials to an authentic transformation towards new generation excellence, both for cashmere wool and pre-consumer baby camel. A continuous progress throughout which wool-based top range fabrics come to life, underlining a smart-oriented vision and culture within Re.Verso™’s 100%-made-in-Italy supply chain.

A well-thought and far-sighted choice aimed at proposing highly innovative fashion materials that can be stylish and responsible all at once, which are also very appreciated by important brands in the field. Gucci introduced cashmere from the Re.Verso™ by A. Stelloni Collection by Mapel in their men’s, women’s and kids’ collections, while Filippa K, following their whole lifecycle, chose materials for the Front Runners collection, which was awarded at the Copenhagen Fashion Summit Design Challenge for its aesthetics and transparent manufacturing process.

An authentic revolution in the mode of production, which pushed the company to increase the percentage of Re.Verso™’s product (currently 30% of its wide offer) and to apply the Re.Verso™ policy on the totality of its reengineered wool offer.

For next season the company has developed new finishes, draps, streaks, velours and, mostly, lighter weights for the top part of the collection. There will be extremely thin baby camel Re.Verso™ fabrics and Re.Verso™ cashmere for a weight of 350 linear g/m per jacket. New diagonal, galles, checkers and microdesign jersey patterns can also be combined with wool weights, both in coats and jackets.

We have experimented new Re.Verso™ “bondea” fabric combinations with micro perforated technical membranes, achieving woolen clothing with waterproof, transpiring and windproof qualities, which had until today been limited only to technical fabrics.

Spiber Inc. with its “Brewed Protein™” materials is a game changer in the fashion industry

C.L.A.S.S. Material hub is our section dedicated to producers of innovative ingredients: fiber, yarn, fabri…

A project by Venezia da Vivere and a capsule collection made in Bemberg™ fabrics, designed by Tiziano Guardini with the illustrator Jacopo Ascari.

May 2023 – Bemberg™ by Asahi Kasei, the unique fiber ob…

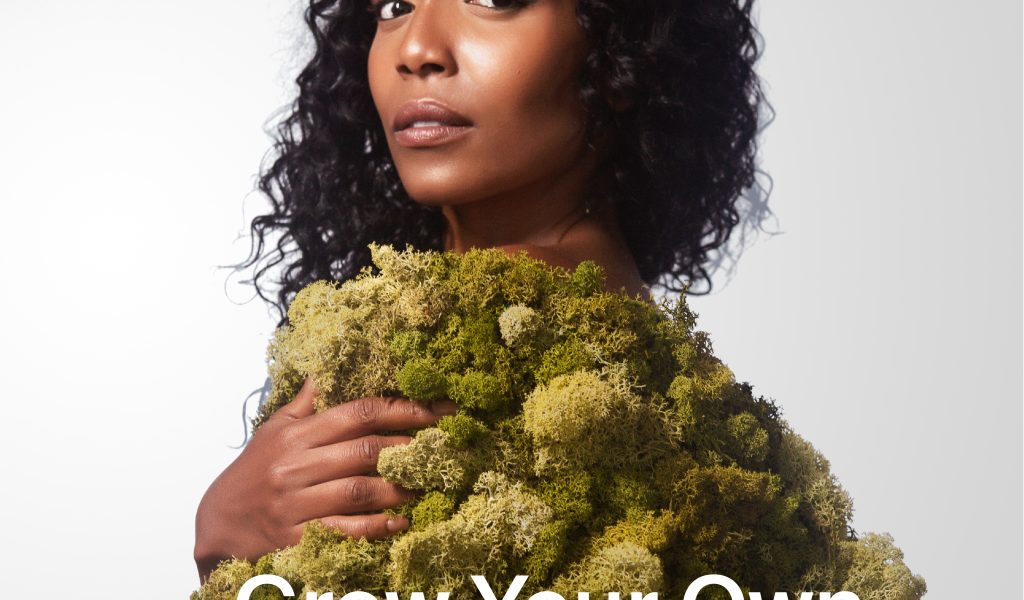

The award, now in its third edition, was set up by Connecting Cultures and C.L.A.S.S. with the aim of creating new visual imagery and innovative communication models in sustainable fashion

“Grow Your Couture” by Piero D’angelo, th…

Our CEO and Founder Giusy Bettoni has been really pleased to attend the 2nd Stakeholder Advisory Board Meeting of the MY-FI project held in Barcelona on May 4th at Leitat Technological Center!

We had the chance to meet the project members a…

Today we are happy to introduce you our new partner in our PROcess x PROgress category: REVECOL® by ERCA

As demonstration of ERCA TCS’s commitment towards responsible innovation, but also thanks to the important appreciation of its R&…

C.L.A.S.S. has always been committed to fostering and activating positive change in the fashion industry, while keeping contemporary consumers informed. This approach is perfectly aligned with the one of Challenge the Fabric that…

C.L.A.S.S. Material hub is our section dedicated to producers of innovative ingredients: fiber, yarn, fabric, leather and accessories.

Today we are happy to introduce you our new partner:

Pozzi Electa S.p.A.Pozzi Electa…

C.L.A.S.S. Material hub is our section dedicated to producers of innovative ingredients: fiber, yarn, fabric, leather and accessories.

Today we are happy to introduce you our new partner: Marini Industrie.

Marini Indust…

ROICA™ V550: the first Degradable Stretch solution for a New Generation of Denim

April 2023 – The international eco-tech yarn innovator and manufacturer ROICA™ by Asahi Kasei leads the way in circular stretch inno…

Since 2007 we have been advocating for a new generation of fashion where the fusion of design, innovation, communication and responsibility shapes an informed and competitive business, able to play both at an economic and social level.…

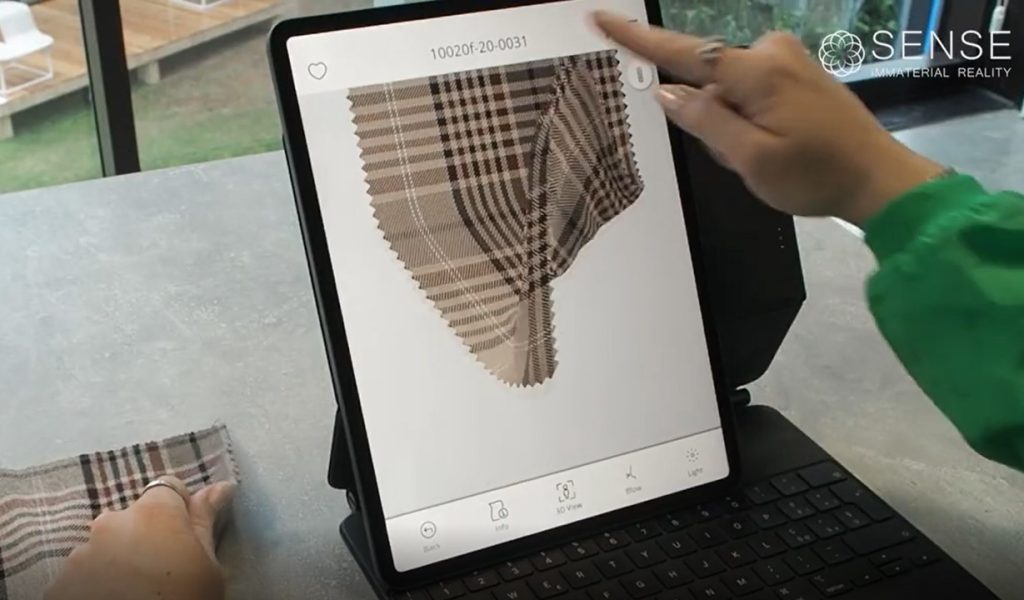

C.L.A.S.S. Future Devices is our area reserved for the new frontiers of digital communication: from virtual reality and haptics to blockchain platforms.

Today we are happy to introduce you our new partner:

Sense – im…